Liquid products to the bag packaging machine YILONG company developed specifically for the liquid packaging materials to the bag automatic packaging machine for four-sided sealed bag, three-sided envelope and back sealed bags...

Product Description

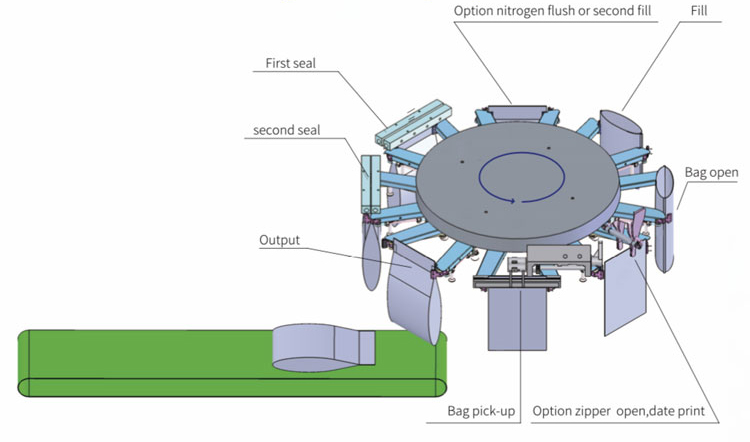

1.Bag Feeding 2.Optional Zipper open and Date print3.Bag mouth and bottom open

4. Product fill 5.Option: Solid :Nitrogen charge,Powder:Bag mouth clean,

Liquid:Secondary filling 6.Heat sealing 7.Heat sealing 8.Output

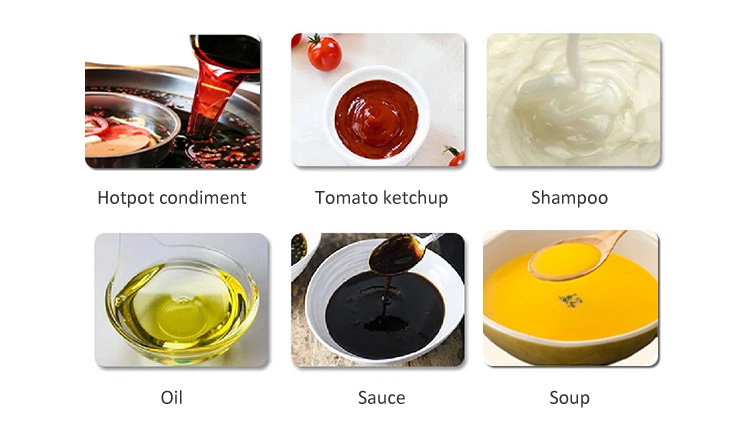

Product Application

Case

bag type and size range

Pack compacity

Available Products

| Power supply | 380v 3phase 50Hz |

|---|---|

| Compressed air | about 5~8kgf/cm²,0.4m³/min |

| Drive method | Cam |

| Fill station | 2 |

| sealing style | straight/net type |

| Workstation | 8/10 station |

| Min bag width | 80mm |

| Max bag width | 305mm |

| Noise from running machine | within 75db |

![]() With a device can against sealing vacant pouches to make sure that if there is no fill, there will be no seal.

With a device can against sealing vacant pouches to make sure that if there is no fill, there will be no seal.

![]() With a device can against sealing vacant pouches to make sure that if there is no fill, there will be no seal.

With a device can against sealing vacant pouches to make sure that if there is no fill, there will be no seal.

![]() Patented gripper system

Patented gripper system

![]() maximum precision

maximum precision

![]() flexible pouch type: stand-up pouches with zipper or corner spouts, quad pouches and pouches with customers’ design

flexible pouch type: stand-up pouches with zipper or corner spouts, quad pouches and pouches with customers’ design

![]() Flexible production speed 15-90 pouches/min.Easy to operate, PLC control, with touch screen man-machine interface control system, easy to operate.

Flexible production speed 15-90 pouches/min.Easy to operate, PLC control, with touch screen man-machine interface control system, easy to operate.

![]() Long work time and lifetime can work 24 hours a day, only one day off for maintenance per month.

Long work time and lifetime can work 24 hours a day, only one day off for maintenance per month.

Easy to operate and maintain, one person is enough.

![]() Easy conversion with different scales, fillers,pumps.

Easy conversion with different scales, fillers,pumps.

![]() High profitability can replace at least 7 workers for packaging.

High profitability can replace at least 7 workers for packaging.

![]() Low energy and maintenance costs, only a few spare parts need to change.

Low energy and maintenance costs, only a few spare parts need to change.

![]() Fast delivery of spare parts, for example, max 3 normal days to reach you

Fast delivery of spare parts, for example, max 3 normal days to reach you

Second fill

Metal detector

check weigher

inkjet printer

third seal

tank

We will contact you within 24 hours